India has never lost touch with its roots. Even as modernization revolves round the globe, our fashion still continues to exuberate grace, subtlety and sustainability.

Fashion evolution in India started with the invent of Cotton Fiber. Long back, around 2500 BC, a civilization flourished in India namely Indus Valley civilization also known as Harrapan Civilization.

It flourished in the Valley near Indus River. The region extended from Manda (Jammu and Kashmir) in the north to Daimabad (Maharashtra) and from Alamgirpur (Uttar Pradesh) in the east to Pakistan (Sutkagan Dor) in the west.

This civilization was also known as the bronze age civilization and many bronze articles have been excavated from the sites of this civilization.

Indus valley civilization excavation and remains show traces of cotton cultivation and it being used as textile material and also for the purpose of trade. The civilization flourished between 3300–1300 BCE and was the first civilizations to carry out plantation of cotton plants and develop techniques for spinning and weaving it into a fabric.

Excavations at the Harrapan cites shows remains of spindle whorls or takli, made of clay, terracotta, stone, and metals like bronze. This was a tool developed by Harrapans for spinning cotton fibres into yarns.

People wore hand-spun cotton garments dyed with natural indigo, showcasing early textile craftsmanship.

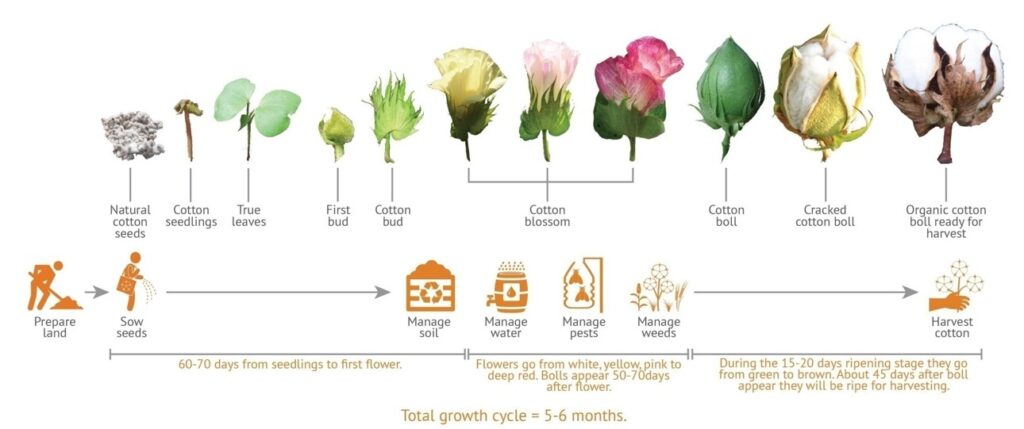

Cotton a plant fiber obtained from the SEEDS of KAPOK Plant, grown on black soil and the favourable climatic conditions prevalent in India. The process of cotton processing carried out in factories now a days, is done by machinery and is as follows:

The ancient method of processing of fibre was carried out manually, from Ginning that is plucking seed Fibre to the process of Drawing and Roving. After roving, the fibres cling to one another in the form of a fluffy thick rope known as sliver. The final step of spinning was done by spindle whorls or takli (refer to the video attached). After spinning, the yarns were woven into a fabric. India, China, Peru and Egypt were the main areas of cultivation of cotton in those primitive times.

Evolution of Cotton Cultivation, Processing & Production from then till now...

Ranging from primitive, ancient times, till medieval centuries, India became renowned for its fine cotton textiles—Muslin from Bengal, Chintz from Gujarat, and Calico from the Coromandel Coast, the eastern coastal belt of India. Cotton cultivation expanded across fertile regions, and spinning and weaving were largely artisanal, done by hand using tools like the charkha. These textiles were major exports, traded across Asia, the Middle East, and Europe.

Then came the time of Colonial Era, where British colonization drastically altered India’s cotton economy. The East India Company, established by Britishers, turned India into a supplier of raw cotton for British mills, undermining indigenous handloom industries. Mechanized mills were introduced by them in cities like Bombay and Ahmedabad, but they primarily served colonial interests. Traditional artisans thereby faced deindustrialization, and cotton processing hence shifted from decentralized village systems to urban industrial hubs.

When Indian government and majorly, Gandhiji understood the aim of British East India Company, the Swadeshi movement commenced. It thereby revived interest in indigenous cotton production and hand-spinning, symbolized by Mahatma Gandhi’s use of the charkha. This era saw a resurgence of cottage industries and a push for self-reliance. By 1947, India had a mix of handloom and mechanized cotton sectors, laying the foundation for post-independence industrialization.

At independence, India inherited a broken cotton landscape. Most of the fertile cotton-growing land had gone to Pakistan, leaving behind just 4.42 million hectares. The early decades focused on self-sufficiency, with government-led initiatives to revive cotton farming and support handloom sectors. The Cotton Corporation of India (CCI) was established in 1970 to stabilize prices and to support farmers.

The introduction of hybrid cotton varieties, notably the H-4 strain in 1970, marked a turning point. The H-4 cotton strain, also known as Hybrid-4 or Sankar-4, was a groundbreaking development in Indian agriculture. Released in 1970 by Dr. Chandrakant T. Patel at the Surat Cotton Research Station of Gujarat Agricultural University, it was the world’s first commercial cotton hybrid. These seeds improved yield and fibre quality, enabling India to expand its textile base. Mechanized spinning mills flourished in cities like Ahmedabad and Coimbatore, while handlooms continued to serve rural economies. However, productivity remained uneven due to rain-fed farming and limited irrigation.

In 2002, India approved Bt cotton—a genetically modified variety resistant to bollworms. This led to a dramatic increase in yields and reduced pesticide use, with Bt cotton covering over 90% of cotton farms by 2014. Cotton production surged, making India the world’s largest cotton producer. Yet, over-reliance on a single technology brought new challenges: pest resistance, soil fatigue, and declining biodiversity.

Recent years have seen a shift toward climate-resilient farming, organic cotton, and regenerative practices. Drip irrigation, precision agriculture, and AI-driven crop monitoring are slowly gaining ground. Despite technological strides, only 30–33% of farms use modern irrigation, and smallholder farmers still face credit and market access issues. The rise of ethical fashion and global sustainability standards has pushed Indian cotton producers to rethink fibre quality, traceability, and eco-certification.

From hand-spun yarn to automated ring spinning, India’s cotton processing has undergone a huge change. Today, the country hosts over 1,500 processing mills, 7 million power looms, and 4 million handlooms. Innovations in dyeing, printing, finishing, texturization and blending have enabled Indian cotton fabrics to compete globally—across fashion, home textiles, and technical applications.

India’s cotton story is not just about fiber—it's about farmers, artisans, technologists, and storytellers. As the industry embraces sustainability and digitization, the challenge lies in balancing tradition with transformation. Cotton remains a symbol of India’s enduring spirit—rooted in soil, spun with purpose, and stitched into history.